Tekmos Talks Newsletters

A newsletter for the semiconductor industry

Tekmos Talks 2015

|

|

||||||||||||

| A Newsletter for the Semiconductor Industry | ||||||||||||

| December 2015 | ||||||||||||

|

Welcome to the final edition of Tekmos Talks 2015. This month we will revisit Tekmos' 2015 New Year Resolutions, share about our ISO Re-Certification, Reflect on IoT, and introduce a new product. |

||||||||||||

| From the Desk of the President, Lynn Reed | ||||||||||||

|

2015 Review of New Year's Resolution Every year in January, I make a list of New Year's resolutions. And in December, I review them to see the results. This was a good year for resolutions, though I sometimes wonder if I am getting better at accomplishing resolutions or I am getting better at writing resolutions that can be accomplished. So here are our 2015 resolutions, and the progress we have made on each. We will bring out programmers for our user programmable versions of our 68XX, 80C51, and 28F010 families.Done. We make and sell dedicated programmers for a number of our programmable devices. We will develop new high temperature standard products. Done. We have introduced our 15530 Manchester encoder / decoder, and out 74373 octal latch. And our 89H51BA microcontroller is in assembly at the time this is being written. We will also work on improving EEPROM performance at 175ºC. Done. These improvements are being incorporated in our new 32Kx8 EEPROM. We will bring out 0.18 micron ASICs Done. We are now quoting designs using this technology. We will expand our Japanese sales. In progress. We continue to invest in the Japanese market. We will expand our use of adapters as an alternative for obsolete packages. Done. We have also increased our ability to test adapters through the use of custom sockets We will add a wafer probe capability. In progress. We have our probe machines working, and have the probe interface hardware on order. There is still time to probe our first wafer this year. We will expand our high temperature (+175ºC) test capability. Done. We have now tested thousands of parts at elevated temperatures. We will complete the product qualification studies on our new 0.35u technology. Done. But just barely. Our 1000 hour HTOL burnin will finish on December 17th. We will perform multiple high temperature reliability studies at 175ºC. Done. A lot of the work has been done at 210ºC, which is a more extreme case. The results have been excellent, though our biggest problem has been the burnin boards themselves. They become brittle after 4000 hours at 210ºC, and will break when handled. Overall, this was a good year for resolutions. Next month I will have our 2016 resolutions. |

||||||||||||

| Re-Certification of 9001/14001, by Jon Gehm, Director of Operations | ||||||||||||

|

Re-Certification of BSI 9001/14001 Well, the New Year is fast approaching. To me, this is always an exciting and somewhat magical time. It gives us the opportunity to take a pause, look at things, and maybe be a little more honest about those changes we seem to have put off throughout the year behind us. Everyone has their own list. Of course we all want to lose a little more weight. We should stop procrastinating whatever that thing that needs to be done in the garage is. And we should probably be a little nicer to whichever aunt, uncle or obnoxious cousin it is that you have been avoiding all year until the holidays. We are all guilty of those lists, and they are always good for a chuckle. But around Tekmos, we are taking those lists a little more seriously this time of year. Our quality system actually demands it. In that light, we are pleased to announce that Tekmos has gone through the auditing process, passed, and received our updated BSI ISO 9001 and 14001 certificates. Around here, we don't just make resolutions, we actually put them in writing. And if I do say so myself, we do a pretty good job of making those goals happen. That is what our customers expect, and what we expect to do for our customers. Of course we are going to be a little nicer to crazy Uncle Joe. And I really am going to lose that weight next year. But even if that doesn't happen, it is nice to know that you can come by Tekmos, and see that some resolutions really are set in stone. That is always a good comfort this time of year, for our customers, and also for our-selves as well. |

||||||||||||

| High Temperature Microprocessor Strategy by Lynn Reed | ||||||||||||

|

High Temperature Microprocessor Tekmos is developing a high temperature microprocessor designed to run at 250ºC, using a SOI process. The development has taken longer than planned due to custom design issues with the SOI process. As a result, we decided to split the project into a SOI version and a bulk silicon version, and make the initial silicon on a 0.6u bulk process. This will allow us to characterize the processor design and verify its functionality. And there is a market demand for parts in that temperature range. This 0.6u process works well at temperatures up to 210ºC, and we have a lot of high temperature experience with designs that use this process. One of our 0.6u gate arrays has 2K bytes of EEPROM on it as well as an 8-bit ADC and 1K of RAM. These are useful components for a microcontroller, and incorporated them into our 8051 design. We have been using a "H" designator for the 8051 series to indicate high temperature. But now that we have both bulk and SOI parts underway, we find it necessary to create new part numbers. In the past, other 8051 vendors have differentiated their parts with a suffix, and so we followed that procedure. Here is our new numbering system for the 0.6u, high temperature 8051s:

We have incorporated these numbers into a new data sheet, which is available on our web site. |

||||||||||||

| Reflecting on IoT | ||||||||||||

|

Tekmos IoT Blog Throughout the past year, we have presented several articles on IoT, the Internet of Things. I was asked if I could summarize the ideas in a short couple of paragraphs. Of course, summaries always leave the writer with the issue of potentially throwing out some of the key ideas that make the topic interesting. I said I would give it a try anyway. The Internet of Things is all about connecting diverse electronics to make them even more useful. The flow of information often starts with analog sensors, measuring almost anything one can think of, from temperature, speed, pressure, and location, to color, voice, and personal characteristics. Often the analog signals are made into digital ones and zeros and transmitted somewhere. There is often some type of processing of this information to add meaning or context. The data can then be used to inform people or machines which in turn take some action. The range of possible uses is extremely wide, from telling where your cat is to turning on air conditioning when someone is anticipated to be in the building. It can be used to automatically order replacement parts when a machine becomes aware that parts are wearing out or sensing that you are at the grocery store and sending a text reminder that it thinks you are running low on milk. But the IoT is not just a cute toy. For example, the amount of money to be saved by smart energy use is tremendous. There are predictions that the major use of IoT for the next several years will be retrofitting to make old machinery more efficient. As one might expect, good things come at a price. As expected, there are a large number of technical issues. We talked about sensors and issues on making electronics smaller by such approaches as stacked die. The article on having someone taking over your car, while you are driving it, points out what is likely the biggest problem of all: making devices so that, either intentionally or unintentionally, the interconnectivity does not lead to major problems. While having your refrigerator send spam may be a humorous annoyance, having one's pacemaker subject to a hacker is truly frightening. During the next year, we will investigate more aspects of the IoT and some of the ramifications of implementing it. We will also look at how the technology is evolving. |

||||||||||||

| Thank You for Reading Tekmos Talks | ||||||||||||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||||||||||||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| November 2015 | ||

|

Unify with Tekmos Welcome to the November edition of Tekmos Talks 2015. This month we will talk about Tekmos' 200th Tape Out, share about Stacked Die and the IoT, talk about customer service and the recent flooding here in Texas. |

||

| From the Desk of the President, Lynn Reed | ||

|

200th Tapeout Tekmos completed their 200th tapeout this month. For reference, we are on our 246th layout, and our 783rd design. So, how can we have 783 designs but only 200 tapeouts? Tekmos uses a technique called merged designs. With merged designs, we combine multiple designs on a single layout. The different designs are activated by bond options during the assembly process. For example, a recent tapeout had a die that contained 4 similar microcontrollers (TK87C749, TK87C750, TK87C751, and TK87C752), plus another 4 dedicated ROM codes, for 8 different part numbers. Tekmos will occasionally make their own MPWs (Multi-Project Wafers), and combine two or more physical layouts on a single mask set. This is how we have more layouts than tapeouts. So why count tapeouts? Because it is an easily defined milestone that has an economic consequence. Once you have tape'ed out, there are no second chances. Unlike PC boards with blue wires, there is no ability to make a minor change. At that point, you are committed. Tekmos currently tapes out about once every three weeks. And the logistics of doing so keeps us pretty busy. Each layout has to be created, and checked. Most layouts have a mixed signal component that requires a manual intervention. Design documentation must be completed, and purchase orders have to be written. Prototype lots have to be tracked all over the world. Wafers are made in Germany, shipped to Taiwan for assembly, and then to Texas for testing, and perhaps back to Germany for the customer. Our two hundredth tapeout is an internal milestone, but one that we take a good deal of satisfaction in achieving. |

||

| Stacked Die & IoT | ||

|

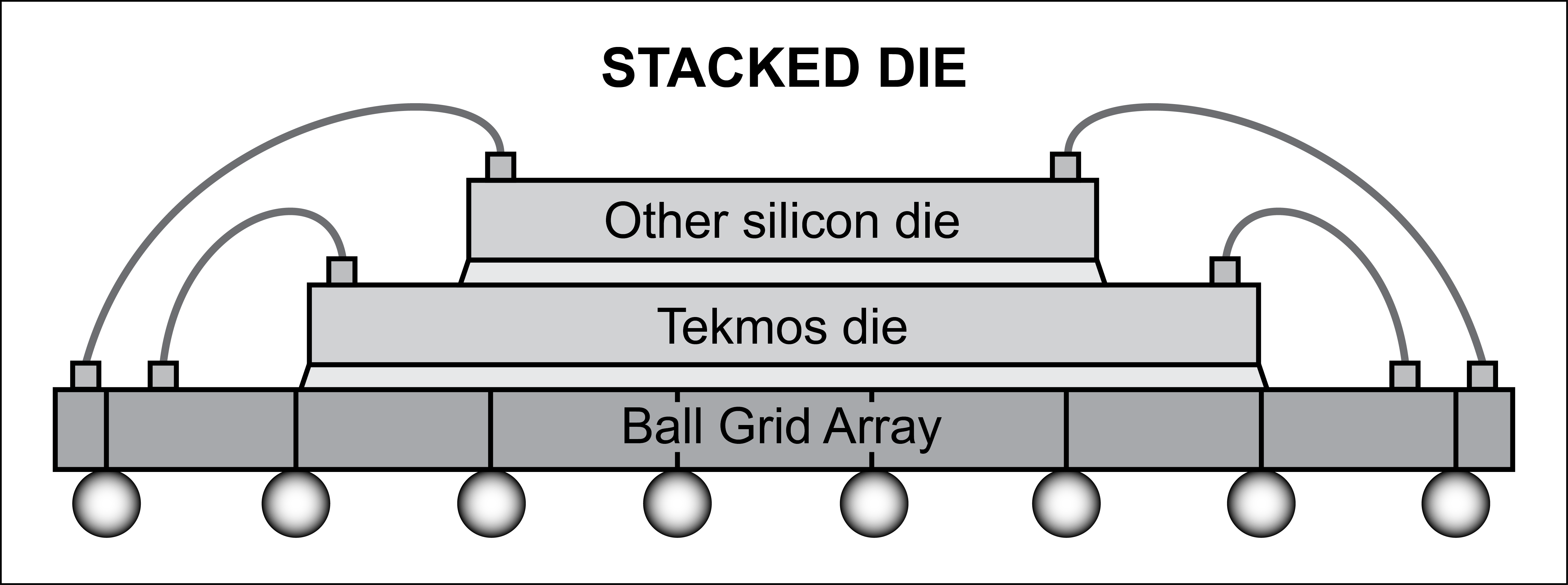

Stacked Die and IoT Most silicon die are packaged in one of a wide variety of packages. The package protects the die, the wire bonds, as well as supplying an interface to the larger geometries of PCBs (Printed Circuit Boards). Since the beginning of the use of packaged silicon, most packages contained a single silicon die.

In the past few years, the assembly technique of mounting one die on top of another within the same package has become more widely accepted. Many of the problems of attachment of the die and rules for wire bonds have been worked out, even for high volume production. There is even talk of whether this Stacked Die approach will replace SOC (System On a Chip). Cost is an obvious advantage of stacked die. First, there are fewer parts on the final assembly on a PCB. More importantly, different silicon processing techniques can be used for each silicon chip in the stack. Each part is optimized for its function and even the silicon processing can be optimized. Often, these parts of the overall design have found widespread use in many applications, driving the cost of the die by the economies of scale. The use of stacked die also has a major positive effect on design activities. If a block of circuity already exists, there is no need to redesign it, saving significant engineering time and cost. Additionally, this lowers risk and increases the likelihood of first time success since, at least this part of the design, is known to be good. One example is a design that requires a unique structured IC with a large amount of Flash memory. Since a Flash die can be purchased, there is no need to include it in the customized structured design. The process used to fabricate the structured design will not need to include the silicon processing steps required for Flash. The customized structured design will have a higher yield and lower cost since it has less circuitry. The higher yield and less expensive processing of the structured design also helps push cost down. Without redesigning the flash circuitry, the design time and cost are lowered. Much of the IoT world requires features that almost describe the stacked die approach. The final overall design is made smaller with stacked die. Handheld electronic devices are one of the major reasons for the rapid advance of the stacked die approach. Then again, an IoT device for tracking the location of a cat or cow cannot be very large either. Time to market is reduced by lessening the amount of design time and increasing the probability of first time success. A new idea for an IoT product can get market share quickly by the use of already made building block chips plus an underlying structured device. The breadth of electronic components that can be stacked is quite wide and the limit is primarily imagination. The use of Stacked Die is expected to be a major method of implementing designs in IoT applications. |

||

| Tekmos Customer Support | ||

|

The Heart of Good Customer Support One of the most costly blunders companies make is failing to identify the difference between the value of a customer and the long-term value of that customer. First impressions are key. Your customer should feel like an honored guest when visiting in person or by phone, conference call, or electronic mail. Providing great customer service at Tekmos is that first impression. It is the way we interact with our customers and achieve increased sales and profits and have that customer return and refer us. Tekmos' Customer Service manager, Renee Dalton says, "At Tekmos I represent the customers in the entire order process from the design, to manufacturing, to the finished product, delivery, and follow up. I put myself in the customer's shoes. The number one customer service skill is listening to our customer; a willingness to listen closely." If you cannot provide that to the customer, you will not achieve their goals. Communicating clearly in a verbal and written fashion is second but goes hand in hand in the communication process. Part of that good communication process is a dedicated web page for customers to visit to find out answers or a portal to the right person for those answers. Customer service is important to Tekmos' organization because it is often the only contact a customer has with the company. Some customers spend thousands and even more per year with Tekmos. Consequently, when they have a question or product issue, they expect the customer service department to resolve their issues. If the company is technical such as Tekmos, engineers are often the go to for answers. So how do you get your engineers to talk with your customers? That's Renee's job, to "wade into the black hole of engineering" and get those answers. She says, "I set the schedule for the products and keep them on track. Communicating with engineers and customers is essential to that process being successful." Another essential to giving good customer service is taking responsibility as a company for if a customer experiences a product or service which isn't what they'd hoped. Dealing with the problem efficiently and effectively is key. A company with excellent customer service is more likely to get repeat business from customers. Consequently, the company will benefit with greater sales and profits. Contrarily, companies with poor customer service may lose customers, which will have a negative impact on sales. It costs a lot more money for a company to acquire a customer than to retain them. Therefore, the efforts that go into maintaining quality customer service can really pay dividends over time. At Tekmos, that is the objective says Renee, "find answers to questions, find solutions to problems, advise customers when products ship, and keep everybody happy. At Tekmos we are proud of the excellent customer service we provide." |

||

| Floods in Texas by Lynn Reed | ||

|

October Flood On October 30th, Austin experienced a very heavy rainfall. In our area, we estimate that 15 inches fell in a 3 hour period. Tekmos is located on a small hill, so we survived without any damage other than a small roof leak. Behind Tekmos is Carson Creek, which did flood. The waters reached our parking lot, but were still 4 feet below our floor. There is a hiking trail that runs along the creek, and has several nice foot bridges that cross the creek. That did not survive. The creek also flooded two of the three roads we use to access Tekmos, and also shut down both highways 71 and 183, which are major roads next to Tekmos. One watershed over is Onion Creek. Onion Creek is a much larger creek, and had the worst flooding. At one point, the flow rate was measured at 120K CFS. For comparison, Niagara Falls was running at 84K CFS the same day. This is a picture of Carson Creek just going over the roadway of the road behind Tekmos. And here is another picture looking upstream. Today (November 2nd), I took a hike along what remained of our trail. The trail has been stripped of its sand, and is now just tar paper and dirt. The large rocks that lined it have been tossed around by the waters. Many of the rocks lining the trail had been left scattered across a nearby field. Here are the remains of one of the foot bridges that crossed the creek. Eventually the creek reached Riverside and Highway 183. At this point, it is in a concrete lined ditch. A 30 foot section of the ditch had been broken off and swept downstream. The antennas in the background are part of the airport. That is why I feel comfortable with using the airports rain totals as our own. Eventually, the creek goes under Riverside. Here, it looks like some of the concrete slabs had become wedged under the bridge, forcing the waters over the top and flooding highway 183. The sidewalk of the bridge was also scoured. |

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||||

| A Newsletter for the Semiconductor Industry | ||||

| October 2015 | ||||

|

Welcome to the October edition of Tekmos Talks 2015.This month we will introduce Tekmos new Programmers, share about Merged Design, more on the IoT, and introduce a new Tekmos Team Member. |

||||

| From the Desk of the President, Lynn Reed | ||||

|

Tekmos Programmers Tekmos makes replacements for legacy microcontrollers, and many of them used EPROM for program storage. EPROM was the first technology that was user programmable, though it was replaced first by EEPROM and later on by flash. Nowadays, it is very difficult to even find a foundry that offers the EPROM technology. When faced with a need for EPROM storage, Tekmos decided to use flash memories, in a stacked die package configuration. This works quite well in the application, but it does require a different programming algorithm. And that is where things become complicated. Tekmos uses the same 4 MB flash memory in each of our devices. But the devices differ in how to access it. The simplest method is used in the TK89C668, which uses a test mode to bring out every pin. The 68HC05 and 68HC11 series are more complicated. These chips did not have the test mode used by the Intel controller families. Instead, they have a bootstrap mode. This requires the loading of a small program into RAM, and then using that program to program the flash memory. Tekmos has received much appreciated support from Elnec in having their programmers support our parts. But we make a lot of parts, and so we had to develop programmers to support those parts who are only sold to a limited number of customers.

Tekmos programmers are based off of the Raspberry Pi computers. These are readily available and well supported with cases and other accessories. The Raspberry Pi is a 3 volt system, and almost all of our controllers are 5V devices. So we designed an adapter card that translated the 3V signals to 5V, and back again. We use this card in all of our programmers. And on top of this card, we designed a third card that holds the specific socket for the device we wish to program. This third card may also hold a DC to DC converter for those devices that require a 10 volt signal to get into the programming mode. We took a standard Raspberry Pi case, had a hole cut in if for the socket, and we were done with the hardware. One of our engineers wrote a program that reads the programming files, downloads a bootstrap program, and then programs the parts. And now we have a programmer. |

||||

| Merged Design | ||||

|

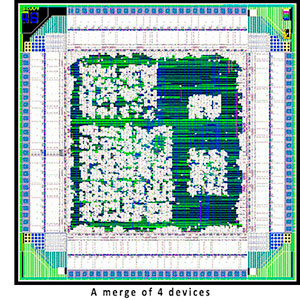

Merged Designs Implementing a design into an ASIC has many steps, some of which are expensive. One such item is the generation of the tooling or masks which are the physical embodiment of each layer. The masks are the tools. Each mask layer is costly to implement in a real physical sense since there is an enormous amount of detail with extremely small sizes and tight tolerances. When making larger quantities of one part type, the costs are amortized over a very large number of parts so that the cost per part is very low. Are there any alternatives if there are only moderate volumes over which to amortize the mask charges? One approach that Tekmos has used successfully is to merge several design functions into one chip type. This can be an especially good approach if the number of required pads is large compared to the amount of circuity. In these cases the die size is dictated by the periphery with large amounts of unused area on the inner part of the layout. This allows the cost of the masks to be amortized over all the circuits. If the size of the die is not affected much, there will be very little effect on the per die cost. This approach has the added advantage of allowing a larger number of identical wafers to be processed further lowering the costs. Additionally, until the die are packaged, there is flexibility on the how the inventory of identical wafers are allocated. The designs are merged into a single layout. The selection of which circuit is activated is done when the die are packaged. Different wire bonds are used to select which design is activated. This approach has allowed Tekmos to make several cost effective ASICs at moderate volumes. The first picture shows the merging of four designs into a single layout. The second picture shows an actual physical layout that incorporates eight different designs plus some RAM. This is a very high number of devices merged but it illustrates what can be achieved. |

||||

| Internet of Things | ||||

|

Is the Internet of Things Digital? We are living during a digital revolution at least that is how it is talked about. There is no doubt that much of our current electronics is digital. Actually, it is not just digital in the way the numbers one to ten are. Internally, it is fundamentally binary, meaning one of two states, a one or a zero. Of course, there are a tremendous number of ones and zeros. This is very convenient for electrical circuitry that is either in one state or the other. It allows for corrections of distortions since a signal anywhere close to zero volts is considered a zero. Likewise, any signal close to the high voltage is considered a one. But the world we live in is not like that. As a room gets warmer, it goes through every possible temperature between its lowest and it's highest. If you wanted to know what the temperature in your family room was while you are in your office, the signal going to your smart phone would be digital. The transition from the continuously variable temperature in your family room to the digital display on your phone is accomplished first by some type of sensor. A component, a sensor, was developed to convert the analog temperature to an electrical signal. This electrical signal also can be any value over the allowed range. Another circuit is also needed to convert this analog signal to a signal with discrete digital values appropriate for the binary world the information would flow into. This is where the real world meets the man-made world of digital electronics. One can imagine that a similar process goes on any time it is necessary to get a real world output from a digital signal. A great example is listening to sounds on your smart phone. Our ears will not do well with digital sounds. The series of ones and zeros is converted back into a smooth, continuously flowing audio signal. The ones and zeros are processed through a digital to analog converter. The analog electrical signal is then fed to a device, such as a speaker, to convert the electrical signals back to vibrating air which travels to our ears. Whenever the real world meets the digital electronics world, something of this nature exists behind the scenes. Many of the most useful implementations of the Internet of Things has interfaces to the real, continuously variable world that requires sensors to have the information enter the digital world. The variety of interfaces to the real world seems endless. A quick look at available sensors at one manufacturer included microphones, proximity sensors, accelerometers, water flow sensors, gas flow sensors, tire pressor sensors, gyroscopes, proximity sensors, thermometers, light meters, heart rate sensors, and light intensity sensors. Yes, most of the guts of Internet of Things is mostly digital but it could not interface to the real world without sensors. |

||||

| Meet Tekmos | ||||

|

Laksh Fox, Engineer I don't use my full name because I end up being called a made up version of sushi : ) How long have you been at Tekmos and what brought your here? I have been here for about 9 months. I came to Tekmos because Lynn Reed presented me with an opportunity to do engineering design. What are your responsibilities here at Tekmos? My responsibilities are a little across the board. I have done a bit of debug, simulation, and layout. What are your favorite tasks or projects to work on here at Tekmos? My favorite project so far has been the layout design of an SOI memory. It has prompted me to learn more about memories and the actual silicon process, layers, etc. What Project are you working on now? I am working on a 256x8 SOI RAM. Please tell us about your professional and educational background. I graduated with an Electrical Engineering Bachelor's. My experience is in power management validation in pre and post-silicon. |

||||

| Thank You for Reading Tekmos Talks | ||||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||||

|

|

||||||

| A Newsletter for the Semiconductor Industry | ||||||

| September 2015 | ||||||

|

Welcome to the September edition of Tekmos Talks 2015. This month we will talk about Interns morphing, share about ASICs, more on the IoT, and introduce a new product. |

||||||

| From the Desk of the President, Lynn Reed | ||||||

|

Interns Morphing to Engineers Tekmos hires college students and assign them to work in various positions. Freshmen serve as operators, running handlers in our manufacturing area. Junior and senior engineering majors may be elevated to technicians, and used to assist engineers in their work. This summer, we have had two people make the transition from Intern to Engineer.

Kelsey Mehlhorn was promoted to being an Assembly Engineer. She is in charge of setting up our in-house assembly operations.

Michael Robinson is now our newest design engineer. He graduated from Texas State University this summer, and decided to join us. He will be working on some of our microcontrollers. We are pleased that they have decided to start their careers with us. |

||||||

| ASICs | ||||||

|

So your ASIC supplier won't supply your ASICs? Many ASIC manufacturers are either no longer around or are not offering ASICs any more. So what do you do if you need more parts? You come to Tekmos. Tekmos has been a trusted source of replacement ASICs (and conversions from FPGAs to ASICs) for almost twenty years. There are many things to consider when generating a new ASIC from a prior ASIC. Since every chip is different, a lot depends on what is contained in the original design documentation. The Tekmos starting point is usually a post-route, gate-level netlist but we can accept RTL, HDL, or VHDL and synthesize the design into the Tekmos library. We simulate the design using the vectors supplied to us to verify we have implemented the netlist correctly. We also run fault coverage on the vectors to make sure that they are effectively exercising the circuit. We prefer 95% fault coverage but we usually accept original vectors with coverages as low as 85%. Sanity checks are always good. A great way to verify that the design and stimulus vectors match the prior design is to apply the input stimulus to real parts and see if the outputs are what we expect. Of course, we need our customers to supply a few of the original design parts in order to make this check. One might think that this is a waste of time and effort but we have had a few instances where the design files supplied to us were not the final version of the prior part. No one wants to try to explain to their boss that, after waiting for many weeks, they now have a supply of working parts that are for the wrong generation system. It is nice to have a physical example of what we are trying to build. Having an actual physical part allows us to verify other characteristics, such as input switching levels and output drive levels. Occasionally we also find that these characteristics are different than what is called out in the specification. To successfully build a new ASIC, it is critical to determine exactly what is required, not just what is said in the specification. Once we are convinced that the netlist and vectors match the prior part, the design is processed with a standard ASIC design flow. The design is committed to physical layout and the effects of the physical implementation are fed back for re-simulation. Once the designer is satisfied that the design still functions, after allowing for the physical layout, tooling is procured and silicon fabricated. Tested wafers are separated into chips and the chips packaged and tested. After you accept samples, Tekmos starts sending production parts to you. So if your ASIC supplier won’t or can’t supply the ASICs you need, come to Tekmos who will supply them. And when you come, bring the original vendor signoff documentation package and a couple of reference parts. That is all we need. |

||||||

| Internet of Things | ||||||

|

The Breadth of IoT Even though we had talked about it before, my non-techie friend asked me “How big is this IoT thing?” I tried to explain again that the IoT, the Internet of things, is really a poorly defined marketing term that is very, very broad. Here is what we talked about. How it wasCars used to be mostly mechanical with a few electrical items. Computers were expensive, room-sized machines that required air conditioning. Long distance communication was either over phone wires or with specialized radio equipment. Music came from either the radio or a vinyl record player. Verbal instructions from parents had more effect on kids than on record players or telephone apparatus. All this has changedWith recent advances, many different technologies have finally grown into each other. Cars are computers on wheels. A hand held smart phone is a computer that plays music and takes great pictures. It’s a flashlight that can be used to deposit checks from home or tell you where you or a friend is. The smart phone can follow your verbal instruction to play music or to place calls. The term IoT is the recognition that all these things can interact. A personal scenarioIt is not hard to imagine that a future evening might include this scenario. You are in a city that is new to you. Your car recognizes you as you walk toward it and opens the door just in time. You sit down and say “Take me to a good, medium priced Greek restaurant that is no more than twenty minutes away.” The car answers “Due to traffic conditions, it will take thirty five minutes to get to the Greek restaurant but there is a good Italian restaurant that is only ten minutes away in current traffic. I can make reservations at either. Which do you prefer?” You answer and the car reads you the current specials and plays Italian music until it drops you in front of your choice. It goes on to find the parking place that it has identified. While this scenario may never happen, it is actually feasible today. It illustrates the working combination of visual recognition, self-driving cars, automatic use of traffic conditions, automatic search and reporting of online information, and the computer choice of appropriate music. It’s not just a fun toy for individualsThe IoT has major uses in utilities, lighting, smart use of air conditioning, remote control of oil wells, dams, air traffic, and much more. If highway vehicles “talk” with each other, they can travel much closer together, faster, and make safer entry merges. The sensing of a stalled vehicle on the tracks can stop a train even before the engineer sees the problem. Water flow in irrigation systems can be modified by weather forecasts. The impending failure of a manufacturing machine can be sensed and new parts ordered and ready. Human fire lookouts can be replaced by visual and infrared sensors that can be alert 24/7 and that do not ever need to be rescued. All these things can happen with interconnectivity. Oddly enough, things not even connected to the internet sometimes get lumped in. I have heard the term IoT used when referring to using a smart phone to adjust a hearing aid. In short, the IoT is the interconnection of everything. |

||||||

| New Product Announcement | ||||||

|

New Product Announcement: 250ºC High Temperature TK74H373 Tri-State Octal D-Type Transparent Latch Tekmos now offers the 250ºC High Temperature TK74H373 Tri-State Octal D-Type Transparent Latch. It has the same pinout as its predecessor, the 74H373 which was designed for less harsh environments. The TK74H373 is designed for use in extreme temperature environments, such as down-hole oil drilling and wireline applications. It can also be used in jet engine applications where it is necessary to interface directly to high temperature structures. The part uses a special high temperature SOI process, with tungsten interconnect, to prevent metal migration. It has gold bond pads with gold bonding to improve bond reliability. The TK74H373 features 8-bit registers with totem-pole 3-state outputs designed specifically for driving highly-capacitive or relatively low-impedance loads. The high-impedance state and increased high-logic level drive provide these registers with the capability of being connected directly to and driving the bus lines in a bus-organized system without need for interface or pull-up components. They are particularly attractive for implementing buffer registers, I/O ports, bidirectional bus drivers, and working registers. The eight latches of the TK74H373 are transparent D-type latches meaning that while the enable (G) is HIGH the Q outputs will follow the data (D) inputs. When the enable is taken LOW the output will be latched at the level of the data that was set up. The TK74H373 is the newest Tekmos high temperature standard product. Tekmos also offers ASIC capability for designs that must be kept proprietary for IP reasons. For more information on any high temperature products from Tekmos, please contact Bob Abrams. |

||||||

| Thank You for Reading Tekmos Talks | ||||||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||||||

|

|

| A Newsletter for the Semiconductor Industry |

| August 2015 |

|

Welcome to the August edition of Tekmos Talks 2015. This month we will talk about IMAPs 2015 where Tekmos presented a white paper at The International Conference and Exhibition on High Temperature Electronics Network (HiTEN) in the UK, and share stories and pictures about our European travels. We will also talk more on IoT and security, introduce a new product, and Tweet-Mos. |

| From the Desk of the President, Lynn Reed |

|

Tekmos European Vacation

Last month, Tekmos both exhibited and presented a paper at the 2015 HiTen Conference in Cambridge, England. Travel and especially international travel can be an arduous experience. So we try to have a fun activity scheduled in our plans. And since the conference was only 3 days long, all of us took an extra two days of vacation to take advantage of the trip and see more sights. When we arrived in Cambridge on Sunday, we walked over to the downtown area, and engaged in punting. Punting is using a 10 foot pole to push a flat bottomed boat up and down the river Cam. None of us had ever punted before, so we hired a professional punter to punt us up and down the river, and give a narrative of what we were seeing. Most of the older colleges in Cambridge are located along the river, and it is a very nice and scenic trip.

Being engineers, we had to try our hands at punting. We were successful, if you define success as not falling out of the boat. Many of the other boaters were quite inebriated, and would occasionally fall out of their boats. Afterward we all drifted back to London and did some of the standard tourist activities, took a river cruise and went up the London Eye, visited the museums, and looked at the Rosetta Stone. And being engineers, we had to visit Greenwich and stand on the Prime Meridian. After all, who but an engineer would travel 6000 miles to stand on a line that someone arbitrarily drew on the ground? |

| IMAPs 2015 |

|

IMAPS - High Temperature Electronics Conference 2015 Tekmos was a sponsor, presented a paper, and maintained a display table at the July 6-8 2015, International Conference and Exhibition on High Temperature Electronics Network at Churchill College in Cambridge, England. This annual conference, which alternates venues between the U.S. and England, is dedicated to high temperature electronics, ranging from the relatively cool 175ºC up to the 1200ºC range for Silicon Carbide. It also covers high temperature materials and passive components. Analog circuits are often required to interface between the sensing of real world parameters, such as temperature and pressure, and the digital electronics that process and transmit the information. As temperatures are raised, the performance of this circuitry deteriorates. Standard processed parts are almost unusable above about 200ºC but the use of SOI (Silicon On Insulator) processing pushes the usable temperature much higher. The Tekmos paper this year was "The Design and Characterization of an 8-bit ADC for 250ºC Operation". Lynn Reed presented the paper written by Lynn and Vema Reddy. The paper describes how the design of an existing 8-bit ADC (Analog to Digital Converter) was optimized for the SOI process. It also presents the characterization of the ADC at various temperatures up to and above 250ºC and shows the effects of increased leakage on the ADC parameters of linearity, accuracy, and conversion speed. The paper shows that these critical parameters may be within a usable range, at least for an 8-bit ADC, to temperatures above those previously thought. The ideas and data presented in this paper point to additional studies and approaches that might be pursued. See the photo of Lynn being presented a plaque to commemorate his presentation. The paper is available here. Attending the presentations does a lot more than just give Tekmos an opportunity to present our research. Listening to the presentation of other papers has led to some consideration of additional techniques that Tekmos may pursue. It is important to know what others are doing. The question and answer period following each presentation gives more insight and understanding than can be obtained from reading the paper alone. Tekmos also had a display table at the conference. While there were several such displays, ours stood out for a couple of reasons. First, because we were a sponsor, our booth was in a prominent place. Attendees had to walk past our display on the way to the dining area. Second, the table had a 48 inch monitor displaying many of the high temperature parts and capabilities of Tekmos. The central figure on the display features a silicon chip in an open ceramic package sitting in the middle of a flickering fire. The picture shows no damage to the part as it sits on burning logs. Around the part and fire, various Tekmos high temperature parts and depiction of potential uses were flashed. We were able to engage a number of attendees in useful conversation and believe this has allowed us to make inroads toward new business. Attendance at the conference was lower than the prior year when it was held in Albuquerque, New Mexico. A couple of factors probably led to this. For many potential U.S. attendees, the extra cost of travel to England was too expensive. Perhaps more importantly, there has been a downturn in the oil industry. While the high temperature electronics industry goes well beyond the oil industry, this industry has been the major source of revenue for pursuing getting electronic components to work above |

| Internet of Things |

|

Hacking the IoT: A Real World Security Problem Fears about nefarious use of IoT have moved from the theoretical to the demonstrated. A Jeep Cherokee, driven on a real expressway with traffic, was hacked and the engine shut down from a remote location, via the internet. This could easily be life threatening. It could make the problem of identity theft, as bad as it is, pale in comparison. "Hackers Remotely Kill a Jeep on the Highway - With Me In it" was the title of an article by Andy Greenberg in Wired. Andy goes on to say: I WAS DRIVING 70 mph on the edge of downtown St. Louis when the exploit began to take hold. Though I hadn't touched the dashboard, the vents in the Jeep Cherokee started blasting cold air at the maximum setting, chilling the sweat on my back through the in-seat climate control system. Next the radio switched to the local hip hop station and began blaring Skee-lo at full volume. I spun the control knob left and hit the power button, to no avail. As I tried to cope with all this, a picture of the two hackers performing these stunts appeared on the car's digital display: Charlie Miller and Chris Valasek, wearing their trademark track suits. A nice touch, I thought.... Andy had willingly worked with the hackers and had been warned that they would do something like this. The time and place of the hack was unknown so that Andy could experience the effect of such a hack. It was set up in a way that it would not be life threatening. None the less, it is sobering. The hackers used the internet, through the entertainment system, to get access. Apparently there are several Jeeps that were identified that they could have hacked. An accomplished engineer friend did not believe me when I told him the story until I showed him the article in Wired. The reality of it is backed up by Chrysler's recall of 1,400,000 vehicles to add a software fix. These hackers did this merely to demonstrate that it is actually possible. Previously, they had gotten little traction with their assertions that this could be done, so they had to prove it. These are the good guys. They are exposing vulnerabilities before real harm is done. Published reports indicate that they are working with Chrysler to show the deficiency and help with the fix. I have made liberal use of the article from Wired because it is the best example of a security problem with IoT (Internet of Things) interconnectivity that I have seen. I suggest reading Wired for this and other informative articles. The IoT is upon us and security is a major issue. If anything, this hack of a Jeep should send a warning message to everyone that security needs to be addressed. It is not clear what the role of government should be but it is clear to me that, as a consumer, I need to be aware. Perhaps it is time to write to our congressmen and ask what they are doing about the problem. I think these problems can and will be solved, but until they are, all developers must be aware of the potential problems of sloppy code. Likewise, all consumers need to be aware of potential problems and push their political leaders toward getting IoT security issues resolved. |

| New Product Announcement |

New Product Announcement, 250ºC High Temperature TK15530 Manchester Encoder/Decoder Tekmos now offers the 250ºC high temperature TK15530 Manchester Encoder/Decoder, a high performance CMOS device intended to service the requirements of MlL-STD-1553 and similar Manchester II encoded, time division multiplexed serial data protocols. The TK15530 is designed for use in extreme temperature environments, such as down-hole oil drilling and wireline applications. It can also be used in jet engine applications where it is necessary to interface directly to high temperature structures. The part uses a special high temperature SOI process, with tungsten interconnect, to prevent metal migration. It has gold bond pads with gold bonding to improve bond reliability. The TK15530 is divided into two sections, an Encoder and a Decoder. These sections operate completely independently of each other, except for the Master Reset functions. The TK15530 integrated circuit is fully guaranteed to support the 1MHz data rate of MlL-STD-1553 over both temperature (-55ºC to +250ºC) and voltage. It interfaces with CMOS, TTL or N channel support circuitry, and uses a standard 5 volt supply. It is offered in a 28-pin Ceramic DIP package. The TK15530 is the latest Tekmos high temperature standard product. Tekmos also offers ASIC capability for designs that must be kept proprietary for IP reasons. For more information on any high temperature products from Tekmos, contact Bob Abrams, Director of Sales@Tekmos.com or call 512-342-9871. |

| Inside Tekmos |

|

Tweet-mos Every now and then, events occur that capture everyone’s attention. Tweet-mos is one such event. A few days ago, I was looking out my window (instead of working), and I noticed a commotion in the parking lot. There was something fluttering in the parking lot, and a grackle was walking around it, trying to determine if it was eatable. I went out to look closer, and the grackle flew off. It was a baby mourning dove that had fallen from its nest. I looked around for a nest, but did not see one. And even had I seen one, the tree is about 30 feet tall, and I don’t know how I could have put the bird back. I also looked around for a mother dove, but did not see one. I thought that I heard one, but could not locate it. The grackle was still around, and the asphalt in the parking lot was hot, so I did not want to leave it. Instead, I brought it inside for discussion as to what we should do. The first step was to name it, and so it became Tweet-mos. One of our employees had experience in raising baby birds, so we entrusted it to him. He identified it as being about 7 days old, and said that it should be able to fly away in another 10 days. We promised to reimburse him for expenses. That was 4 days ago. He was brought back for a visit today. Tweet-mos is still alive, it has grown, its eating, drinking, and pooping. So there is a good chance it will survive until he is ready to be released into the wild. |

| Thank You for Reading Tekmos Talks |

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| July 2015 | ||

|

||

| From the Desk of the President, Lynn Reed | ||

|

How High Can You Go? We recently characterized our high temperature 8-bit ADC. While it was designed for 250ºC operation, we kept raising the temperature until we reached 320ºC. We stopped there for a number of reasons. The first being that our oven could not go any higher. It was rated to 350ºC, but we think that the test wires running out of the oven were providing a heat sink that lowered the temperature. And we were concerned that our test setup or the package itself would fail. All of this led to the question of how high can we go? Ultimately, there is a temperature at which silicon becomes a conductor. I recall from school that was 377ºC, but that was a long time ago, and I can't find information confirming that. The digital logic was working well at 320ºC, and I suspect that it could go quite a bit higher, and perhaps up to 350ºC. On the other hand, the transistor leakage was definitely affecting the analog circuitry, and if it was higher, it would affect the digital circuitry as well. The fab has authorized baking bulk wafers at 310ºC for EEPROM reliability testing. Somewhere above than we may start to see threshold shifts in the silicon along with other process issues. Our package should start coming apart around 300ºC. The weak points are the solder used to hold on the lid, and the epoxy used to hold the die in place. We did exceed this temperature in our testing, and we presume surface tension kept the package from falling apart. This could be addressed with a gold die attach, and with a brazed on lid. The part we were working with has aluminum pads and gold wire bonding. Over time, we should see corrosion between the gold and aluminum. This can be addressed by using a gold - nickel - palladium coating on the bond pads. Finally, our test board was rated for 300ºC. It didn't appear to be damaged, but then the part was not at 320ºC for more than 15 minutes. This can be addressed with a ceramic PC board. So how high can we go? The absolute limit will be set by the transistor leakage interfering with the circuit operation. The exact temperature will depend on the design of the circuit, but will be in the range of 350ºC. The answer also depends on how long we have to be there. At 250ºC, the reliability goal is 10,000 hours, or just over a year. Reliability halves with every 10ºC rise in temperature, and so the year of operation at 250ºC may be down to a few days at 320ºC, and to a few hours at 350ºC. The exact failure could be either transistor parameter shifts, or bond pad corrosion. Even though we can get to 350ºC, practical considerations will limit us to 310ºC. We are going to start an experiment with our reliability monitor to see if semiconductor parameter shifts are occurring above 300ºC. We will report the results in the future. |

||

| Internet of Things | ||

|

Home appliances and IoT (Internet of Things): Really useful or a Fad? I was reminiscing with some old friends, mostly engineers, about technology and how many people do not make use of what they already have. One of the engineers said he never could understand why his sister would never set the time on her coffee maker. It just sat there flashing "12:00". It suddenly occurred to me, if the coffee maker had been connected to the internet, it could have gone out, determined where it was, and set the correct time for that time zone, even allowing for daylight saving time. Up until now, I have generally thought that connecting home appliances to the internet was a gimmick, not of any real use. That some people would pay for it to impress their friends for a couple of weeks and never use it again. I am beginning to see that the IoT (Internet of Things) may be the next step in making technology accessible for people who have no technical aptitude. Imagine a coffee maker that not only sets the time but one you can have a conversation with. With voice recognition, it could ask if you want coffee started 10 minutes before the time set on your alarm clock which also has IoT connection. It could ask if you want it to turn-off automatically if you have not taken any coffee for some period of time or if it should shut off automatically one hour after your alarm went off. These are useful things that my friend's sister would use, if she did not have to figure it all out. By connecting the security camera with your smart phone, it is possible to converse with someone making a delivery. As IoT devices become more interconnected, the technology can ask, "Do you want me to connect the doorbell and security cameras to your smart phone. Should I enable a connection to your spouse's smart phone? While this is possible today, very few people who might really want it are willing or able to go to the trouble of making it available to themselves. The smarter IoT devices will easily move people past what seem to be huge hurdles that prevent the use of technology. The advantages for sight impaired people are obvious. It is hard enough for some people with normal eyesight to take full advantage of technology with smarter and more interconnectivity, the task of implementing the technology gets much less daunting. Imagine feeling of greater autonomy of a visually impaired person who can now handle many of his own technology issues. The coffee maker and security camera examples are only the beginning. Imagine having your garage door ask if you meant to leave it open as you drive away. Picture your stove telling you that you left it on when it realizes you are not in the house anymore, or that you have not put any item on it for some period of time. It could even ask you if you want to shut it down remotely, or without a response from you, shut it off. Most people would not use these features unless one of the appliances asked the user if he wanted it done for him. While I do not plan to move into the market of making IoT connected appliances, I am beginning to see their advantages for some people, especially for those that can't be bothered. The use of IoT is not just for people who are uninterested in reading the instructions or who find that whole thing too tedious. It is help for everyone to reap the rewards of technical advances without, what some consider, the pain of using them. |

||

| A Great Technical Conference | ||

|

Many companies are finding great and creative ways to be involved with their customers. In the rapidly changing electronics industry, targeting customers who use electronic components in any specialized field, communicating with the right targeted customers can be challenging. Taking the same approach used in the mass advertising of consumer products would be a colossal waste of time and money since such a small percentage of the audience would have any interest in the product or, in many cases, even understand what the products are. Freescale Semiconductor has taken an approach that seems to work quite well. In late June, I attended the Freescale Technical Forum in Austin. (Conveniently located in Tekmos' home town, Austin.) I do not have the official count of attendees but it was huge, taking over multiple ballrooms on multiple floors of the JW Marriot Hotel. According to my count, there were 269 sessions on many, many topics. Several sessions were hands on and their rosters were filled to capacity. I do not intend to give a review of the conference here. That can be found in other sources. I expect one or both keynote presentations will be available on the web. Additionally, there was a large room set up with many displays of products that contain Freescale components, an ideal place to make contact with technical people from a wide range of companies. There was a large truck outside that was set up to display many IoT products. The conference also highlighted many of Freescale's partners. The combination of Freescale Semiconductor with NXP creates the fourth largest semiconductor company in the world. It should be noted here that Tekmos is a partner with Freescale. We developed many replacement processors and controllers that Freescale made up until the fab was wiped out by Fukushima Tsunami. The main point of this article is to comment on what a good conference Freescale Semiconductor put on and how this type of forum can help the entire industry. I should also mention that this is the tenth year of the Freescale Technical Forum. I encourage our readers to seek out information from Freescale Technical Forum other sources about the content of the conference especially the technical. The technical content is outside the focus of the article, but I do encourage the reader to look into the new products announced at the conference. The Tuesday keynote speaker was Gregg Lowe, the CEO of Freescale. Much of the emphasis was on IoT in automobiles. Again, seek out a web version of the presentation. Freescale processors and sensors are very compatible to this aspect of the IoT. One of the human interest stories was a dramatization of how Freescale's partner, Cadillac, using technology from Freescale, created a system that sets off an alarm if the driver falls asleep. This alarm likely saved the life of a Freescale employee's grandfather. The Wednesday keynote speaker was Steve Wozniak. Always good to hear his opinions expressed with a fair amount of wit. I expect this wide ranging talk to show up on the internet too. I encourage both technical and non-technical people to look into what Freescale is doing, especially in the IoT space. Their processors and sensors are a great fit for automobiles that are already in the design phase. Look for the technical content on the web. If you get a chance, go to the conference next year. |

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||||

| A Newsletter for the Semiconductor Industry | ||||

| June 2015 | ||||

|

||||

| From the Desk of the President, Lynn Reed | ||||

|

A Moving Experience

Tekmos has doubled in size for the past two years. Space was definitely a problem, and with our lease up last April, we started to look for new space in October. In hindsight, we started off with two mistakes. The first was that we should have allocated 9 months for the search instead of 6. The second error was that had we checked our lease, we would have noticed that it ended in March and not in April. So we were down to 5 months, and didn't know it. After about two weeks of searching, we found the perfect place. It was on the low end of our space requirements, but the location was nice, and the internal build out was a good match. We negotiated the lease, and signed in January. The city of Austin has different levels of reviews for zoning permits, based on the amount of work that has to be done. We were advised to scale back the modifications we had wanted in order to fit in the lowest level of reviews. A longer review meant that there would not be time to complete the work before our current lease expired. This was just another case of dreams being overturned by reality. We had made the decision to hire an interior decorator. Our contractor recommended Karen Burris of Ice Interior Design. This was easily the best thing we did during the move. She did a wonderful job of choosing colors, carpet, furniture, wall art, and arranging for subcontractors to do various tasks.

|

||||

| Internet of Things | ||||

|

IoT For Young Creators In a departure from commercial aspects of the IoT (Internet of Things), this month's article is about how the IoT can help foster the creative spirit in people even before they are out of middle school. It gives an example of how a desire for something cool might move from an idea to a simple system and then with more and more enhancements. All this is aided by the building blocks that come with the IoT. One of the problems that young people have is they want to design something but they do not have much equipment or many materials to work with. If the thing they want to put together is at all complicated, they may need to start from scratch to build all the components. As an example, a middle schooler would like to create something cool. He gets the idea of being able to remotely monitor something in his home. The idea occurs to him: "Wouldn't it be neat to know we are running out of milk without looking in the refrigerator." In years past, a kid could come up with some crude way to determine if the weight of the milk container was less than a predetermined amount. The only output might be a light that comes on. It was very difficult to make this system be any more sophisticated than this. With the IoT today, the building blocks to get take this idea a lot farther already exist and are readily accessible. With the computer he already has for doing his homework, he can go a lot farther without needing to develop a lot of sophisticated additional equipment. A connection could be made from the refrigerator to the computer to process the "out of milk" message and even record when it happened. The computer could be programmed to ring a bell, or even taking it farther, play a recorded message.

|

||||

| New Product Announcement | ||||

|

New Product Announcement, TK68HC805P18 Tekmos now offers the TK68HC805P18 as the latest addition to our line of microcontrollers. It is designed to be a drop-in replacement for other 68HC805P18 parts that have been hard for our customers to obtain. The TK68HC805P18 microcontroller features a 4-channel, 8-bit analog-to-digital (A/D) converter, a 16-bit timer with output compare and input capture, a serial communications port (SIOP), a computer operating properly (COP) watchdog timer, and 21 input/output (I/O) pins (20 bidirectional, one input-only). The memory map contains 192 bytes of RAM, 8064 bytes of program Flash (for user code), 512 bytes of boot ROM. This device is available in DIP or SOIC Packages. Tekmos continues to be the "go to" supplier when there are problems finding obsolete parts or when additional parts are needed after the date for EOL (End of Life) purchase has passed. Tekmos makes a variety of microcontrollers, microprocessors, and other miscellaneous standard products to satisfy these needs. Tekmos also continues to make custom ASIC replacement parts. Customers are aware that buying from Tekmos ensures pin for pin, drop-in replacements that can be counted on to work in their applications, without worry about the quality of parts purchased on the grey market.

|

||||

| Tricks of the Trade Show | ||||

Planning for a tradeshow/conference can take a good year preparation depending on the extent of your organization's involvement in the event from exhibiting, presentations, level of event sponsorship, and the marketing "giveaways" the company will use at the event. Marketing gimmicks can include a raffle for an item or a trip, giveaways such as pens, flash drives, reusable bags or stress balls, all with the logo of the company. Then there are the high dollar gimmicks which can make an event very interesting. A recent conference attended had a noteworthy number of attendees of company executives and service operators from various branches of the oil and gas industry. Getting noticed by attendees is key to whether your participation in that conference is worthwhile. An exhibitor's job is to get seen and to draw in attendees to market their product or service. Some exhibitors will do just about anything for that "lead". At this particular conference it was noticed distinctive promoting at one booth a full bar with bartender to serve any attendee between the hours of 10:30AM to 4:30 PM during the main day of the conference. At every network break there was a guarantee for a long line which also benefited nearby exhibitors. Another booth right next to that one had a magician doing tricks complete with microphone that drew in crowds. While yet another exhibitor had a putting green contest and the winner was added to a raffle for a very expensive putter. Taking "Murphy's Law" into the mix is critical to an effective conference and to ones state of mind; if you plan for everything that could go wrong, you are ahead of the game and ready to have a successful event. Make sure you also have a unique attention grabber for your booth and staff it with knowledgeable people that can answer attendee's questions. Expect tired feet and minds by the end, and be sure to create a written report of the conference time line so that all leads, picked up knowledge, and any unexpected events are studied and learned from for future events. Follow up is key-without it the time and money has been wasted. Follow up should be systematic-no one knows which lead may turn out to be a breakthrough account. Instinct goes only so far in evaluating a lead. |

||||

| Thank You for Reading Tekmos Talks | ||||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| May 2015 | ||

|

|

||

| From the Desk of the President, Lynn Reed | ||

|

Tekmos New Logo & Look Along with the move to our new facilities, Tekmos is getting a new logo.

So how did this happen? Our current logo is just our name in the common Ariel font. We stepped out of the box when we added a maroon underline. It worked, but it was pretty bland. The act of moving into a new building means that we have to pay for a sign. Our artist suggested that it was a good time for a new logo, so I turned him loose. What I got back was our name in all caps, a more distinctive font, and a stylized chip. Many companies pay staggering amounts of money for a graphic symbol that is to represent their company. AT&T has a stylized globe. Mercedes has their three point star. McDonalds has its golden arches. And Tekmos now has a chip. And I love it. What I like the best is that the graphic represents what we do. And that is rare in the world of logos. The logo can also be easily modified for special applications. Here is a variation at may use on our shipping boxes.

And here is a modification of our Hot Chips logo.

Perhaps the most difficult aspect of our new logo was the color red. The first pass had a red that was different on different monitors and when printed. This was a problem since almost all of our documents are electronic. After a few go-arounds, we settled on a red that is the same in every media. We are now implementing the logo on business cards, stationary, boxes, brochures, data sheets, and the web site. And with that, we get a whole new set of challenges, which I may talk about later.

|

||

| Internet of Things | ||

|

Thinking about the IoT, 3rd article in a series IoT is a very nebulous term that can boggle one's mind. It's like coming to grips with the number of stars in the universe or the distance to the Andromeda constellation. The IoT is likely to encompass billions of devices communicating with people or other machines. With over seven billion people in the world now, it seems likely, that in time, there will be many billions of devices interconnected. With cell phones, iPads, computers, wireless mice and keyboards, printers, Roku, home security, smart meters, etc., my household alone has over half a dozen devices per person communicating with other devices. This does not begin to include the device types that will see widespread usage soon. I am not currently able to track my cat but I do not need a key to open or start my car and my tires tell me when they need attention even when they are turning at 1000 RPM. For those directly involved in developing the capabilities and technologies that will be necessary for IoT, at some point it becomes necessary to focus on the technologies and expertise that will be necessary. It appears that most products will incorporate a variety of technologies, so broad an array that it seems likely that even large corporations will need to develop partnerships to combine all that is required. This is more true for smaller companies. It may be small companies that can act and react quickly that will win market share in this new arena. It seems that any company would do well to focus on its core strengths and see how they can be adapted to this new arena. Another approach that is quite useful for companies entering this arena is to try to imagine what the characteristics are of the end products they will likely be involved with. Some of the capabilities that are likely necessary are a communication link, some processing, and an interface to some type of analog device, such as a microphone, accelerometer, pressure transducer, thermometer, etc. It is likely that there will be some way to put these components together with a power source, perhaps with battery power management. Will big data or the cloud play a role? The type of company will have a major effect on how the issues are approached. Companies that deal primarily in software can, in many cases, change direction more easily. The use of Agile and Scrum techniques lend themselves to the quick change in response to the environment. Companies that are primarily focused on hardware development, cannot change as quickly. They are more likely to have a large amount of capital committed before it is known if the approach taken was a good one. Tekmos is studying how best to play in the IoT arena. We are pursuing partnerships at the same time we are putting together plans that emphasize how our core strengths are a big asset to other companies in IoT. After all, we are primarily a B2B company in that our devices are incorporated into other companies’ designs. We are developing IoT partnerships that include both companies with complementary technologies and with the initial customers for our IoT products. This will be an interesting ride for Tekmos and all other companies that seek to participate in the IOT. |

||

| Meet Tekmos | ||

|

Renee Dalton, Customer Service Associate How long have you been at Tekmos and what brought your here? I started with Tekmos February 2015. What are your responsibilities here at Tekmos? I am the Customer Service Associate and it is my pleasure to help customers by providing product and service information, and resolving product and service issues. What are your favorite tasks or projects to work on here at Tekmos? I have been enjoying getting to know our customers and my team members here at Tekmos. I am finding the semiconductor industry fascinating. What Project are you working on now? I am working on learning all the wonderful services that Tekmos has to fulfill the needs of its customers. Can you offer any suggestions to Tekmos clients to make their experience more efficient and successful? Please be as specific as you can about what your needs are. The more information I have the sooner I can get you the solution. Please tell us about your professional and educational background. I worked for many years in the Austin Area School District and decided that I would like to learn something that was different. The semiconductor industry is a very good change and I'm happy to say very different.

|

||

| Market Trends by Bob Abrams | ||

|

Trends in Legacy Parts at Tekmos Tekmos is frequently called upon to develop ASICs that our customers can no longer purchase from the original vendors. For projects of this type, the customer may have the original design files which makes the project fairly straight forward. Another type project occurs when it is desirable to produce an ASIC from an FPGA that is no longer available. Tekmos has successfully developed many such devices. A very different type of project at Tekmos starts when a standard part is made obsolete by a vendor. While a letter usually goes out to customers stating that a part will soon be considered obsolete, customers do not always buy enough parts when the "Last Time Buy" notice is sent. Often this is because the customer cannot accurately predict customer demand on a legacy product. When there is still demand for a customer's obsolete product, he is faced with the difficult decision of trying to buy parts from several distributors, go to the grey market with its questionable part quality, redesign the product, or abandon a product that still has significant demand. One other alternative is to go to Tekmos and ask if Tekmos will build what had been a standard off the shelf part starting from only the datasheet for the part. Many Tekmos standard parts were brought to life in response to this type customer need. Our website has many parts types that were originally for only one customer but we saw the advantage to many customers if we made the part more widely available. Listing these parts, once developed, makes it easier for other customers to replace that obsolete part. An added advantage of buying the parts from Tekmos is completely eliminating any worry about the pedigree of a part. We only sell parts which we have fabricated so there is no question of their origin. The standard part type most requested so far this year is our TK80C51FA which replaces Intel, NXP, and Atmel 80C51 families. It is a microcontroller with 256 bytes RAM, A PCA (Programmer Counter Array), and a watchdog timer. The second most requested part type so far this year is the TK87C751 which replaces the NXP P87C51. While it is a derivative of the 80C51, it is designed to provide the 80C751 architecture in a small package with a hardware Two Wire Interface. It has 64K ROM and a 128 x 8 scratchpad RAM. Details are available on our website. The third most requested part type this year has been the TK68HC711E9 which replaces the Freescale MC68HC11E9. The fourth most requested part this year has been the TK80C188EWC which replaces the Intel TN80C188EB. The fifth most requested part type this year to date is the TK68HC11K1 which replaces the Freescale MC68HC11K1. A full description of each of these parts can be found in their datasheets here. Intel, NXP, Atmel, and Freescale are trademarks of their respective companies. Although each of these part types is pin-for-pin compatible with the device it replaces, these parts are not the same part as made by the original manufacturer. Tekmos strongly suggests trying samples of our parts in customer systems before placing an order. We have seen cases where minor parametric differences can cause system issues. If you have interest in these or other legacy microprocessors, FPGA conversions, or ASIC conversions, please contact us.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| April 2015 | ||

|

Welcome to the April edition of Tekmos Talks 2015. Tekmos is moving to a new and larger location in Austin at the end of the month. We will introduce Lynn Reed, President of Tekmos and his story about SXSW. We will talk about new technology, and the future of Tekmos chips, and share more on Internet of Things. |

||

| Meet Tekmos | ||

|

HOW LONG HAVE YOU BEEN AT TEKMOS? Tekmos was founded by me and my partner, James Betts, back in 1997. That means we have been here 18 years now. That is a record for me, as I have never worked anywhere for more than 7 years prior to Tekmos, and most jobs were 5 years or less. WHAT ARE YOUR RESPONSIBILITIES HERE AT TEKMOS Since I'm the President, I am responsible for everything. Finance and Engineering take up more of my time than they should, since those VP slots are currently open. WHAT ARE YOUR FAVORITE TASKS TO WORK ON? I am an engineer by trade, and so I really love being involved in engineering tasks. However, I have to admit that while I enjoy doing analog design and layout, these are tasks that need to be delegated to others. WHAT PROJECTS ARE YOU WORKING ON NOW? Our biggest task is to reposition the company as an ASIC provider that supports new designs being developed for the Internet of Things (IoT). Tekmos ASICs will be the bridge between standard products that offer a 95% solution and the customer application. To get there, we have to improve our ASIC development procedures, become better in stacking die in small packages, and develop test capabilities for QFN packages. PLEASE TELL US ABOUT YOUR PROFESSIONAL EXPERIENCE AND HOW IT RELATES TO TEKMOS. I have been in semiconductors forever. My Master's work was in bipolar processing. Then I moved to MOS after graduation, and then to ASICs in 1981. I have been there ever since. The ASIC market, and particularly gate arrays, has seen its share of ups and downs. The 2000s were a significantly down period, and many suppliers left the market. This has left Tekmos well positioned to take advantage of the developing IoT market.

|

||

| Internet of Things | ||

|