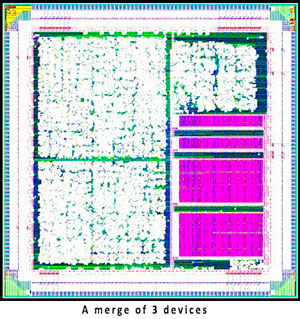

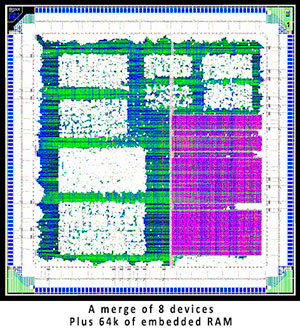

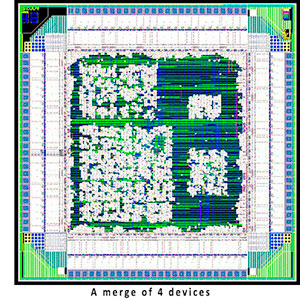

Merged Designs

Tekmos can merge multiple designs onto the same die. Unlike MPW (Multi Project Wafer) which have different types of die on a wafer, merged designs have different designs within each die. The same die is then repeated across the wafer. Since each die can be used for any of the designs, every good die can be used even if one of the designs in it is no longer needed. It allows us to allocate the die from the wafer run to meet the exact needs of our customers.

Merged designs allow the mask costs to be shared over multiple designs, effectively reducing the mask costs for each design on the chip.

This image shows four different designs embedded within the same die. During the assembly process, bond options will activate one of the designs, leaving the other three disabled.

Merge Criteria

Merging designs is not always a good approach. Each die will be larger and therefore more expensive unless the chip is pad limited. (The size of the chip is determined by the number of pads on the periphery, rather than the amount of circuitry.) The decision to merge devices is largely determined by projected volume. For low volumes, the cost of the making of the masks contributes more to the cost per part than the cost of processing the silicon. At high volumes, the cost of the mask is amortized over many parts, making the reduction in die cost more important. At high volumes, each die should be as small as possible, so that there are more die on every wafer processed.

The decision whether to merge designs into one chip is more complicated when the designs are very different in size. Whether the differences are in the amount of circuity or in the number of pads required, the inclusion of a large design will greatly affect the number of smaller designs on each wafer processed. The decision whether to merge designs must take into account the number of die required of each type and how the size of one affects the others.

Different required locations of the power supply pinouts from one design to another can also be a problem. Digital I/O signal pads are easily shared between designs, even when the output drives are different. Once the location and polarity of the supply pads are in fixed for one device, they are established for that chip and cannot be relocated or polarity changed for other designs on that chip. While a supply pad at a fixed location does not have to be wire bonded to a package pin, it still occupies one I/O buffer position on the chip. Omitting bonding it to the package may affect the power distribution.

Merging in Reliability Monitors

Tekmos makes many different ASICs. Running long term reliability studies is difficult since the mixture of parts changes over time. For the monitoring of reliability over a long term, it is desirable to use exactly the same reliability monitor structure. Tekmos addresses this by merging our reliability monitor into most designs and using it to collect data.

Our reliability monitor is a small, two pin circuit that has ring oscillators and frequency counters. The ring oscillators are designed to identify specific reliability problems such as hot-electron injection, threshold shift under bias, and metal migration.

Since the reliability monitor is small, we can insert it without affecting the ASIC performance. Typically, it is hidden and is only available when activated by a bond option. Sometimes the customer is also interested in the data and may map it into their design as a readable port on their data bus.

Final Thoughts on Merging

Merging designs is just another tool that Tekmos has for producing cost effective ASICs. It is not suited for use for all applications. But it can be very effective when it is needed.

|

|

|

Request for Product Information

To request information on your Application Specific Integrated Circuit click this button:

Microprocessors

Other Products

Main Office

Tekmos, Inc.

14121 Highway 290 West

Building #15

Austin, TX 78737

Phone: (512) 342-9871