Tekmos Talks Newsletters

A newsletter for the semiconductor industry

Tekmos Talks 2012

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| December 2012 | ||

|

Welcome to "Tekmos Talks December," featuring highlights of 2012 in our quest to reach out to Tekmos clients, engineers, and the semiconductor community. We would like to take this opportunity to thank all of our customers, suppliers, manufacturing representatives, sales people and distributors. This year we had an incredibly exciting year because of all of you, and 2013 looks just as promising. |

||

| From the Desk of the President | ||

|

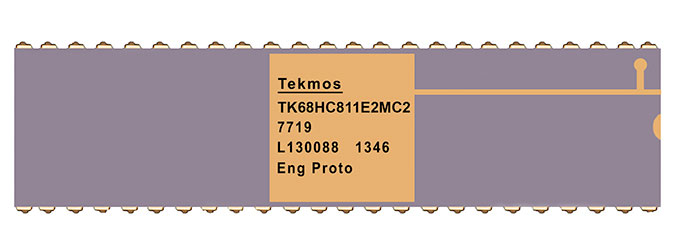

Product Development/Company News 2012 The year 2012 was a good one for Tekmos. After the 2011 Sendai Earthquake, Tekmos obtained the rights to the Freescale 68XX microcontrollers. This year saw us bring these parts into production. We have made the B, C and J versions of the 68HC05 and the A, D, E, K, and KA versions of the 68HC11 family. Each family contains memory variations with ROM, without ROM, and with Flash. Our 80C186/188 EB series went into volume production, and our 89C668 microcontroller hit new production highs. And while we are not done yet, we are nearing the end of our recreation of the 68020 microprocessor. We brought out our first 250ºC ASICs, using a high temperature SOI process. Rated at 250ºC, the circuit performed well at 305ºC during an engineering test. We can now claim to make the hottest ASIC in the world. We are developing these high temperature products to serve the oil and aviation markets.

|

||

| From the Desk of Director Operations, Jon Gehm | ||

|

Quality Control Tekmos continues as a BSI ISO 9001:2008 registered company and is committed to quality excellence. That commitment is employed through a Quality Management System of the design, test, packaging and shipping of fabless semiconductors. Outsourced activities include wafer fabrication, part assembly, and testing. Tekmos has passed the first annual Continuing Assessment Audit from BSI. This is an important part of maintaining our ISO 9001:2008 certification.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| November 2012 | ||

|

Welcome to "Tekmos Talks December," featuring highlights of 2012 in our quest to reach out to Tekmos clients, engineers, and the semiconductor community. We would like to take this opportunity to thank all of our customers, suppliers, manufacturing representatives, sales people and distributors. This year we had an incredibly exciting year because of all of you, and 2013 looks just as promising. |

||

| From the Desk of the President | ||

|

Product Development/Company News 2012 The year 2012 was a good one for Tekmos. After the 2011 Sendai Earthquake, Tekmos obtained the rights to the Freescale 68XX microcontrollers. This year saw us bring these parts into production. We have made the B, C and J versions of the 68HC05 and the A, D, E, K, and KA versions of the 68HC11 family. Each family contains memory variations with ROM, without ROM, and with Flash. Our 80C186/188 EB series went into volume production, and our 89C668 microcontroller hit new production highs. And while we are not done yet, we are nearing the end of our recreation of the 68020 microprocessor. We brought out our first 250ºC ASICs, using a high temperature SOI process. Rated at 250ºC, the circuit performed well at 305ºC during an engineering test. We can now claim to make the hottest ASIC in the world. We are developing these high temperature products to serve the oil and aviation markets.

|

||

| From the Desk of Director Operations, Jon Gehm | ||

|

Quality Control Tekmos continues as a BSI ISO 9001:2008 registered company and is committed to quality excellence. That commitment is employed through a Quality Management System of the design, test, packaging and shipping of fabless semiconductors. Outsourced activities include wafer fabrication, part assembly, and testing. Tekmos has passed the first annual Continuing Assessment Audit from BSI. This is an important part of maintaining our ISO 9001:2008 certification.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| October 2012 | ||

|

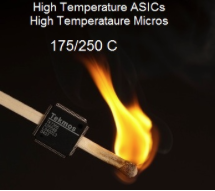

Welcome to Tekmos Talks October. This month's newsletter will share about Tekmos' Guarantee, Tekmos Quality Standards, and News Highlights of company activities and accomplishments for September including the successful launch of our High Temperature ASIC and High Temperature Micros 175/250ºC, the hottest in the world! |

||

| From the Desk of the President | ||

|

Tekmos Guarantee Tekmos guarantees that our chips will work, or we will fix it at our cost. And fortunately, most chips do work the first time. But when they do not, we have to determine what went wrong before we can fix it. ASICs tend to be easy to debug. That is because they are fully defined, and so the operation of the circuit is well understood. If there is an ASIC failure, it is usually an interface problem involving I/O levels. There is the published specification, and that real specification that is determined by the system that uses the ASIC. The chip can fail if there is a difference between the two. We have a saying that we always get what we ask for, but that may not be what we want. Microcontrollers are much more difficult to debug. We produce the chip, but the operation is determined by the software. And since we make replacements for older microcontrollers, we are frequently in the situation where all we have is the binary executable file, and the source code is long lost. The problems also frequently occur at long time periods, beyond the time span that we can easily simulate. Simulations become difficult beyond one million clocks, which represents less than 1 second in real time. A chip that fails after a minute cannot be easily simulated. So what do you do with a piece of plastic that fails to respond after a minute, with an unknown embedded program, and no external clues? The first approach is to study the code. If we don't have the source, we can disassemble it and produce a listing that is almost legible. Then we search for common mistakes such as reading undefined bits, and performing subsequent operations such as AND or OR which assume that the undefined bits are known. There can also be combinations of operations that might exercise hardware in ways that we might not have considered, such as changing baud rates in the middle of a transmission. Looking at the code will solve half of the problems, which leaves us with the more difficult problems. That is when we turn to emulators. As part of our development cycle, we build FPGA based emulators for most of our processors. The emulator allows us to run our design, executing customer code, in customer systems before we committed to silicon. The nice thing about an emulator is that we can synthesize a logic analyzer into the emulator along with our micro design, and use it to debug the problem. If all else fails, we can always use ion-beam technology to verify internal signals, though we have been fortunate to never have had to do that. Once the problem is understood, then it can be fixed, either in software or through a design revision of the chip.

|

||

| From the Desk of Jon Gehm, Director of Operations | ||

|

Tekmos Quality Control Tekmos has passed the first annual Continuing Assessment Audit from BSI. This is an important part of maintaining our ISO 9001:2008 certification and is a fantastic opportunity to show off our continually improving Quality Management System. The process is a bit like spring cleaning, you are not terribly excited about the event, but you have the opportunity to go through the old, decide what you liked and didn't like, do away with the not useful, and make plans and room for what you want over the next year. We have gone through the closets, dusted, cleaned and polished. We find that just when you think you have done something as well as it can be done, there is always room to do it a little better still. That is the philosophy we bring to Tekmos every day and what we will be bringing to our customers throughout the next year.

|

||

| Tekmos News Highlights | ||

|

Tekmos Travels: In September, Tekmos participated in a vendor show at Halliburton where a lot of interest was expressed in our High Temperature ASICs and microcontroller products. Tekmos Manufacturing: In Tekmos' constant efforts of providing excellence to our customers, we purchased a new 320 pin tester to upgrade our test capacity. This replaces an older 224 pin tester, and will allow us to test high pin count ASICs with our own test facilities. Tekmos Product Development: Tekmos received a rush order for a ROM version of the 87C751. The customer required a SSOP Package, and the flash die we use in the TK87C751 would not fit. The ROM is a smaller die and fits in the small SSOP Package. We taped out at the end of September, and plan on delivering prototypes in late October.

|

||

| Manufacturing Representative Highlight | ||

|

Astrorep Inc. Astrorep Inc. began successfully representing quality electronic component manufacturers in the Metropolitan New York and Northern New Jersey market in 1968. Since its inception, Astrorep has maintained a design centric focus assisting their customers with technical and commercial expertise. Working closely with their customers engineering, purchasing, and logistics departments the Astrorep team fully understands their customers' requirements and direction. This leads to their ultimate objective, influencing their customers' choice of product, in their design. With effective design and sales strategies, Astrorep Inc. expanded its' territory in 2005 into the Mid-Atlantic and Chesapeake Regions under the name Envision Design Tech, an Astrorep Inc. Company. This expansion was initiated by request, from their principles with a need for effective engineering and sales coverage in these two additional markets. Effectively servicing a broad range of market segments including, industrial, military, communication, and medical for all three Regions requires a synergistic line offering with broad appeal and sustainability. Having the ability to continue to supply the needs of long term programs found frequently in the military and medical markets with the constant changing and upgrading of components creates a potential design nightmare. The solution for Astrorep in these cases is Tekmos. The ability of Tekmos to offer solutions in these situations has on many occasions helped our customers continue to support long term programs containing discontinued product, long lead time items, or extremely high price increases. These solutions are sound and guaranteed to work, as our customers have come to realize. The Tekmos offering of Microcontrollers, Asics, and Logic conversions offers the flexibility needed for these demanding designs. Astrorep, Inc. territory covers the Mid Atlantic states (New Jersey, Eastern Pa, Metro NY, Long Island) and Chesapeake territory (Delaware, Maryland, D.C., and Virginia). Submitted by Mike Villanti - Astrorep - President.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| September 2012 | ||

|

Welcome to Tekmos Talks September. This month we will address unusual requests from industries looking for electronics that operate with a higher voltage and announce Tekmos' new Surplus Parts Program. Tekmos is proud to be invited to Halliburton's Vendor Day Expo this month where we will exhibit our High Heat ASIC & High Heat Processors for extreme environments. Tekmos Talks will also share sales highlights news, tape outs on 4 different products, and shipments on 3 new micro controllers. |

||

| From the Desk of the President | ||

|

High Voltage ASICs We frequently have customers come to us with unusual problems. We had a customer that had an old 5 volt ASIC that they needed more of. This is not a problem. But they wanted to include a driver chip that had a +/- 5 volt output. And that was a problem. The challenge is how to get 10 volt operation out of available processes that are set up for 5 volts or less. Many of our 68XX microcontrollers use an 0.6u EEPROM process. This process uses special high voltage transistors that are rated at ~18 volts. We needed 10 volt operation, and chose to create a gate array that used these high voltage transistors everywhere. This gave us the process, but we still had several design issues. We were a little worried about speed, since we had to more than double our "L's" in order to support the higher voltage. However the loss of speed due to the increase in "L" was offset by the higher voltages, and so performance was not a problem. It turned out that our biggest problem was the inputs. Normally, inputs use a ratioed inverter. A TTL input is a ratioed inverter that is set to have a threshold of 1.4 volts, which is exactly in the middle of the TTL range. In this case, we were working off of a +/- 5 volt supply. As far as the chip was concerned, ground was the -5 volt supply, and the new TTL input thresholds were between 5.8 and 7.0 volts. This is an impossibly tight target for a ratioed inverter. Instead, we made a simple P-channel comparator, and use an internal resistor string between +5 and ground to establish the threshold. The rest of the chip was straightforward digital logic. This chip was a good example of using a current process in a legitimate but unusual way to achieve superior performance to meet the customers' goals.

|

||

| From the Desk of Jon Gehm, Director of Operations | ||

|

Tekmos Quality Control Tekmos is in the process of conducting a series of internal audits using the ISO 9001:2008 standard. To help do this Tekmos went the extra mile and had three of its employees participate in Internal Auditor training to better prepare them to effectively conduct these audits. Internal audits are one of the requirements to maintain registration as an ISO 9001:2008 company. It is also an opportunity for a company to identify opportunities to improve the quality of its internal systems. The internal audit requires a rigorous hands on approach to assess all of your processes and procedures to determine if they are in line with the ISO standard and your documented system. Internal Audits are a Quality Management System's best friend. Findings from these audits lead directly to improvements in the effectiveness and efficiency of the management system. One of the most important components to successful internal audits is to have employees involved in the process. Involving your employees helps create the feeling that everyone has an important contribution to make to the company and its goals.

|

||

| Tekmos Sales Highlights | ||

|

Sales Highlights from Bob Abrams:

|

||

| New Surplus Parts Program | ||

|

Surplus Parts Program August 2012 Tekmos achieved tape out on 4 different products; 2 military ASICs, 1 new microprocessor the TK68HC711D3 and a High Voltage ASIC of 10 volts. We continue to provide products for fields of defense, oil and gas, aerospace, and the automotive industries. August 2012 Tekmos shipped 3 new microcontrollers: two with ROM codes TK68HC05C8A and TK68HC05L28. Tekmos is pleased to announce the launch of its Surplus Parts Program with the TK68HC11D0. Tekmos provides quality solutions for applications in the fields of oil and gas exploration, oilfield services, automotive manufacturing, medical applications. Tekmos is successful at providing our customers with sustainable, customized semiconductor solutions.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| August 2012 | ||

|

Welcome to Tekmos Talks August, and one of the hottest months of the year. Many industries are looking for electronics that operate in extreme environments including high temperatures such as in deep hole drilling and jet aircraft. It is only appropriate to announce this month Tekmos' achievement of an ultra high temperature ASIC. Tekmos Talks will also share news on product schedules, an article on extreme environment technologies, and highlight a manufacturing representative. |

||

| From the Desk of the President | ||

|

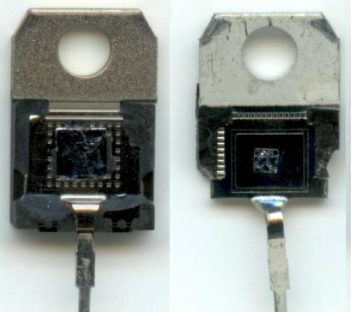

High Temperature ASICs Tekmos shipped our first 250ºC ASIC in July. It was made using the X-FAB 1.0u SOI process. I would like to discuss some of the things we learned from our first ASIC. To begin with, while the first ASIC was designed to work at 3.3 volts, the process is better suited for 5 volt operation. The nominal transistor thresholds are high, and that causes severe performance degradation at 3.3 volts. We were able to make the design work, but there are enough issues with working at 250ºC without adding voltage problems. We used a gate array technology to implement the design. Gate array technologies are based on a routing grid; the smaller the grid, the higher the gate density, and the lower the cost. Sometimes, you can make a tradeoff between a tighter grid, and the possibility that DRC errors will be introduced by the router. Fixing a handful of DRC errors is no big deal, so an extra hour of development time is a good tradeoff against perhaps a 5% reduction in cost. But in our initial pass with the SOI technology, we made a tradeoff that resulted in thousands of errors, and took about a week to correct. We plan to relax our grid on our next chip. The design of the SOI transistor makes it impossible to route over it using metal 1. This is because of the substrate contacts we have to include in the source of each transistor. We compensated for that by including poly tunnels in our basic transistor design, and by providing additional room for the metal 1 routing in cells. This made our basic gate array "block" larger, and we did not increase the transistor sizes accordingly. As a result, the ratio of routing capacitance to gate capacitance rose, and we were forced to do a lot more post-route load fixing, that hurts performance, which was doubly painful considering the reduced performance with the lower operating voltage. With our larger grid, we will also make wider transistors. We still have some characterization to do on the results, and I'll talk about that later.

|

||

| Extreme Environment Technologies for Space and Terrestrial Applications | ||

|

NASA Article Article by Tibor S. Balint*, James A. Cutts, Elizabeth A. Kolawa, and Craig E. Peterson Over the next decades, NASA's planned solar system exploration missions are targeting planets, moons and small bodies, where spacecraft would be expected to encounter diverse extreme environmental (EE) conditions throughout their mission phases. These EE conditions are often coupled. For instance, near the surface of Venus and in the deep atmospheres of giant planets, probes would experience high temperatures and pressures. In the Jovian system low temperatures are coupled with high radiation. Other environments include thermal cycling, and corrosion. Mission operations could also introduce extreme conditions, due to atmospheric entry heat flux and deceleration. Some of these EE conditions are not unique to space missions; they can be encountered by terrestrial assets from the fields of defense, oil and gas, aerospace, and automotive industries. In this paper we outline the findings of NASA's Extreme Environments Study Team, including discussions on state of the art and emerging capabilities related to environmental protection, tolerance and operations in EEs. We will also highlight cross cutting EE mitigation technologies, for example, between high g-load tolerant impactors for Europa and instrumented projectiles on Earth; high temperature electronics sensors on Jupiter deep probes and sensors inside jet engines; and pressure vessel technologies for Venus probes and sea bottom monitors. We will argue that synergistic development programs between these fields could be highly beneficial and cost effective for the various agencies and industries. Some of these environments, however, are specific to space and thus the related technology developments should be spearheaded by NASA with collaboration from industry and academia. The pdf url for the full article can be accessed by the title and authors above or via the link noted. Page 10 has an excellent diagram of commercial and military applications.

|

||

| Tekmos Manufacturing Representative Highlight | ||

|

Active Sales Associates Tekmos is pleased to have Active Sales Associates as a manufacturing representative. Active Sales Associates provides highest quality solutions for applications in the fields of oil and gas exploration, oilfield services, industrial instrumentation, medical applications and contract manufacturing. We seek to understand our customer's expectations prior to committing our best in the industry support. Once committed, we focus on successful implementation of those expectations. Our goal is to gain preferred supplier status and create demand for the products offered by the manufacturers we represent. Active Sales Associates offices are located in Houston, Texas, home to the world's premier oil and gas energy exploration and production companies. Oil business electronic applications are characterized by requirements for reliable operation at extremely high temperature in harsh environments over a specified length of time. Board level systems developed by these companies twenty five years ago are still satisfying current applications and plans are to continue using the technology as long as they can economically procure the parts. Our customer's ability to extend the life of designs enhances profitability by avoiding the high cost of redesign and retraining of users in the field. Manufacturing efficiencies gained over time also contribute to improved profitability. The down side to extended design life is lack of availability and soaring prices of aging semiconductor components. Eventually the OEM is faced with a life time buy decision and eventual costly redesign. We recently completed a High temp ASIC program for a high reliability oilfield application. This was a success because of years of experience with designing ASICs and the technical knowledge of the fab processes from the engineering personnel at Tekmos. Because of Tekmos' excellent work, we have been presented with a new high temp processor opportunity. Thanks to Tekmos, Active Sale Associates continues to be successful at providing our customers with sustainable, customized semiconductor solutions replacing unavailable, high price, aging semiconductor devices.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| July 2012 | ||

|

Welcome to Tekmos Talks July. This month Tekmos will share news on future endeavors, quality control, sales highlights, and introduce our summer interns. Tekmos is proud to support future innovative thinkers for the engineering field. |

||

| From the Desk of the President | ||

|

Accessing Newer Technologies The newer fabrication technologies provide substantial performance advantages of increased speed and reduced power. They also provide the disadvantage of increased mask cost. And this makes many opportunities with lower volumes uneconomical. But there is a way around the mask costs. Most foundries offer shuttle runs. A shuttle run divides the mask into multiple regions, and puts a different customer's design into each region. The mask cost is shared by all of the customers, and is proportional to the area used by each design. The fab then runs a lot of wafers with the shuttle mask set. When the run is completed, the wafer is divided up, and each customer receives a small number of die. While the individual die is expensive, the total cost is much less than using a dedicated mask set and wafer run. Additional wafers can be run using the same mask set, allowing small to medium volumes. The economics are interesting. Assume a $500K total mask set charge, and a $4000 wafer cost. A 5x5 mm die represents 1/16th of the mask area, and would appear 165 times on a 300 mm shuttle wafer. The mask charge is reduced from $500K to $32K, while the die cost rises from $1.50 to $24.00. This makes the volume breakeven point for buying a full mask set be 20K units. There are a lot of opportunities that have volumes much less than 20K units. The economic feasibility exists. We now have to productize it in order to offer low cost ASICs in the 65 to 180 nm range. And that will be the topic for a future newsletter.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| June 2012 | ||

|

Welcome to Tekmos Talks June newsletter. Tekmos is excited to announce product news milestones and the addition of a new manufacturing representative in Compass Technology. This months' Tekmos Talks will also share news about travels to the HiTec 2012 Conference in Albuquerque, our high temperature ASIC, and Sales highlights. |

||

| From the Desk of the President | ||

|

High Temperature Electronics Conference I attended the HiTEC 2012 (High Temperature Electronics Conference) in May. The conference alternates every other year between the UK and Albuquerque. While listening to the paper presentations is always educational, the real value in conferences is the opportunity to talk with prospective customers, and to visit the exhibit area and see which companies are exhibiting and what products they are featuring. The amount of Federal R&D support has been dramatically reduced over the past few years, and that was reflected in a reduction in the amount of research papers. This was partially made up with an increase in papers from the larger semiconductor companies. Both TI and Analog Devices are making a renewed effort to offer high temperature products. There were more companies exhibiting than two years ago, and there were more semiconductor products available. We must always question how Tekmos compares to the competition in our high temperature offerings, and I think that we are doing well. It appears that most >200ºC chips are still produced internally by the users themselves, and that we are the only ones offering high temperature ASICs to run at 250°. Tekmos has achieved "tape out" on a high temperature ASIC designed to run at 250°C. I also note that our internal developmental work is on a par with the published papers. And I think we should expand our efforts and publish our own results in a future conference. Albuquerque is a nice city, and I always enjoy visiting there. The presence of Sandia Peak overlooking the city adds a natural backdrop that is missing from many other cities.

|

||

| Tekmos Product Development & Sales News | ||

|

Tape Out Tekmos is pleased to announce milestones in "tape out" for 2 microprocessors; TK68HC05B16 and the TK68HC11KA. Both microprocessors are used in automotive applications. The product development need and subsequent "tape outs" on these 2 microprocessors came about as a result of the closure of the Sendai Fab. Tekmos Sales Highlights: Tekmos achieves record shipments in 2nd quarter of our TK80C188EB microcontroller. Tekmos books new orders and sees increasing demand for our TK89C668 microcontroller replacement. Tekmos ships 11 different ROM coded microcontrollers of the TK68HC05J1A. Tekmos progresses with AEC Q100 program for automotive qualification. Tekmos books new orders from customers in China for TK80C51FA and TK89C668 products.

|

||

| Tekmos New Manufacturing Representative | ||

|

Tekmos Announces Manufacturers Representative for Upstate NY Compass Technology, Inc. - Upstate New York We are pleased to announce that Jon Caron of Compass Technology will be representing us in the Upstate NY marketplace. Compass Technology will represent all Tekmos products including our complete line of replacement microcontrollers, ASIC and FPGA conversions, standard part replacements and new custom designs. These products will support most commercial, industrial, high temperature, military/defense and medical product requirements. contact: Jon Caron phone: 781-999-0853 Territory: Upstate New York

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| May 2012 | ||

|

Welcome to "Tekmos Talks" May newsletter. We have been very busy working around the clock to meet demands from our customers. The 2011 natural disasters in Thailand and Japan resulted in the disruption of the manufacturing and supply chains causing a global shortage of components driving Tekmos' need to ramp up production. May's "Tekmos Talks" will focus on our work to meet the global shortage of chips and share about Director of Operations, Jon Gehm's visit to Taiwan to meet with our supplier Greatek as part of our continued commitment for quality control. Tekmos is also very proud to announce the addition of Fred Board Associates as our manufacturers representative for the territories of Arizona, New Mexico and Nevada. Tekmos High Temperature ASIC and High Temperature Micros 175/250ºC for Extreme Environments...hot chips! |

||

| Tekmos Samples 3 New Microcontrollers | ||

|

New Microcontrollers Tekmos is working around the clock to help meet demands for microprocessors, sampling three new ones in the TK68HC11D0, TK68HC11E1 and the TK68HC11K1. As of mid-April, Tekmos sampled more than 20 customers around the world, and received both positive feedback and orders. These processors continue to address the shortage from the closure of the Sendai fab.

|

||

| From the Desk of Jon Gehm, Director of Operations | ||

|

Quality Audit As part of Tekmos' ongoing Quality Control Standards, I traveled to Taiwan to meet with our supplier, Greatek to perform an audit. An audit is never an event one looks forward to. There seems to be a queasy feeling, or a need to put up your guard, that people associate with this type of event. This reaction seems to be universal. Mention audit and people get a pained look. They turn away. I imagine the feeling is similar to being a leper, in the olden days. My tin cup is my spiral notebook. The security badge clipped to my shirt, the old cape and cane. Hopefully I smelled better than lepers of old, but one is never sure. People move away quickly, with forced smiles. But there is an aspect to these events that I truly enjoy, and that is the travel. Nothing compares to the glimpse of another way of life, through other cultures, with the opportunity to see and briefly share in different ways people choose to live. Travel is a chance to understand what others may value in other parts of the world. While I may look for similarities in business practices, I find the greatest enjoyment in discovering our differences. While my stay was less than a week, I have the snapshot of memories that come to mind throughout the day. The country is teaming with industry and activity. Buddhist and Taoist temples are scattered throughout the countryside and what seemed to be random locations along city streets. I explored the late night markets, with local food smells and the rapid fire sound of intense negotiations being done in local dialects. I visited historical locations, such as the Chiang Kai-shek memorial hall, with a giant bronze statue of the former leader. And, of course, Taipei 101, which had been the tallest skyscraper in the world, prior to the latest new monstrosity, located in Dubai. While I was impressed with the level of professionalism in the quality and management systems I viewed at Greatek, those experiences are summed up in tightly worded reports and polite reviews with key personnel. As important as they may be, it will be the smells, the smiles and the sights and sounds of Taiwan that I will remember with the greatest fondness. Those memories, along with the local pineapple cakes I brought back for my son's to sample. The cakes received mixed reviews, I might add. And that is as it should be.

|

||

| Tekmos Extends Availability of Older Parts | ||

|

Tekmos extends availability of older parts for micro controller replacements, ASIC replacements, FPGAs conversions, Standard Products and Select Specialty Memory. Tekmos provides older parts and supplies a growing line of standard products that includes 4Mb FPGA Serial Configuration Memories, a 28C94 Quad UART, and a 74C3893 Futurebus Transceiver. We also have the 68HC24 Port Replacement Unit which has been used in hundreds of systems to replace the original Freescale component.

|

||

| Tekmos Announces New Addition | ||

|

Fred Board Associates We are proud to announce the addition of Fred Board Associates, as our manufacturer's representative for the territories of Arizona, New Mexico and Nevada. Fred Board Associates is headquartered in Scottsdale Arizona and can be reached at 480-994-9388. Fred and his team will support all Tekmos products including our replacement micro controllers for l Intel, NXP and Freescale products, FPGA and ASIC conversions and new chip designs requiring both analog, digital and custom functionality.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| April 2012 | ||

|

Welcome to the second issue of "Tekmos Talks". April's issue shares "big" news on prototypes for new parts, a successful audit of Tekmos by a major automaker, as well as take this opportunity to pay respect and remember the people of Japan on the one year anniversary of the earthquake and tsunami that devastated Sendai and the northeast coast on March 11, 2011. |

||

| Tekmos Product Breakthroughs | ||

|

New Products

We here at Tekmos have been very busy since the new year working on replacement processors for Freescale who closed its Sendai plant and shifted remaining production capacity to other facilities and foundry partners, such as Tekmos. The Sendai facility had been producing microcontrollers, analog ICs and sensors products. Japan accounted for 13.9% of all global electronic equipment factory revenue in 2010 and suppliers accounted for more than one fifth of global semiconductor production. As part of the Tekmos - Freescale Technology exchange, Tekmos has accelerated its development of 68HC05 and 68HC11 microcontrollers in response to the shortage. In cooperation with Freescale, we are offering replacements for many of the affected processors. Every product we sell is 100% guaranteed. We are excited to announce we have two successful prototypes for new parts that work very well and currently are sampling: TK68HC11E1 and TK68HC11K1. We have completed the second pass through the Fab. We continue to do sampling and have received production orders for TK68HC11E1.

|

||

| Tekmos News About Quality Standards | ||

|

BSI ISO 9001:2008

Our goal here at Tekmos is to be the service and quality leader for the markets we serve. Jon Gehm, Director of Operations for Tekmos, went to Taiwan the 1st week of April to do a quality audit on one of our major assemblers, Greatek. Quality and reliability begins during the design of all Tekmos products and continues. Tekmos makes it a practice to regularly audit all of its suppliers. In the month of March Tekmos conducted an audit of one of its wafer fabs, X-Fab located in Lubbock, Texas and was impressed and pleased with the results. Tekmos is also very pleased to announce that we have successfully just completed a 4 day audit conducted with a major automaker.

|

||

| Tekmos' Commitment to Combat Counterfeiting | ||

|

Counterfeiting

Those of us in the industry are very aware of the serious problem about counterfeit parts and Tekmos is committed to combating it. Over half of the people we speak with who buy on the "gray market" are unsure if they have counterfeit parts showing up in their inventory. As a service, Tekmos has set up to test thousands of "gray market" parts from customers who purchased elsewhere, to verify and re-screen the parts to see if they are legitimate and meet spec. Tekmos is about trust from the day of inception... always a trusted supplier. Tekmos is a member of the Global Semiconductor Alliance.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

|

|

||

| A Newsletter for the Semiconductor Industry | ||

| March 2012 | ||

|

Welcome to "Tekmos Talks", a newsletter to reach out to Tekmos clients, engineers and the semiconductor community. Last year we had an incredibly exciting year thanks to our customers, and 2012 looks just as promising. In this first issue of "Tekmos Talks" we will share news about our ISO 9001:2008 certification from BSI, our commitment to supply product to meet the demands of the semi-conductor and microprocessor community, exciting new product breakthroughs as well as introduce you to the Tekmos Team. As the year progresses, we are looking to expand our reach and continue to bring new and innovative solutions to the marketplace. Thank you for choosing Tekmos, we greatly appreciate our customers. |

||

| Tekmos achieves ISO 9001:2008 certification from BSI | ||

|

BSI ISO 9001:2008

Tekmos is a BSI ISO 9001:2008 registered company and is committed to quality excellence. That commitment is employed through a Quality Management System of the design, test, packaging and shipping of fabless semiconductors. Outsourced activities include wafer fabrication, part assembly, and testing. ISO 9001: 2008 certification gives Tekmos improved customer satisfaction with independent assessment and certification of our management systems. This certification demonstrates to our customers, competitors, suppliers, staff and investors that we use industry-respected practices and consistently provide product that meets customer and applicable regulatory requirements. ISO 9001 is by far the world's most established quality framework, currently being used by 1,064,000 organizations in 178 countries.

|

||

| New Product Breakthroughs | ||

|

High Temperature ASIC's A worldwide shale gas and oil revolution has given Tekmos the opportunity to demonstrate its innovative High Temperature ASICs 225ºC and 125ºC to meet the oil and gas markets needs for drilling. Oil wells are measured downhole for a variety of parameters important for oil production. Temperature, pressure, and nuclear logging techniques where things like hydrocarbon % in the rock, porosity, lithology (composition of the rock) and water salinity all incorporate devices using high temperature ASIC's. As we all continue to work toward improved forms of clean energy Tekmos high temperature ASIC's will be useful in that pursuit including drilling for geothermal energy. Learn about Sandia National Laboratories' work about the technical challenges of high temperature well logging and the benefits of geothermal energy and drilling.

|

||

| Tekmos Product Updates | ||

|

68HC05 & 68HC11 Microcontrollers Tekmos has accelerated its development of 68HC05 and 68HC11 microcontrollers in response to the shortages created by the Sendai earthquake. In cooperation with Freescale, we are offering replacements for many of the affected processors.

|

||

| Thank You for Reading Tekmos Talks | ||

|

Thank you for reading Tekmos Talks and helping us celebrate 20 plus years. Sincerely, Lynn Reed, President

|

||

Main Office

Tekmos, Inc.

14121 Highway 290 West

Building #15

Austin, TX 78737

Phone: (512) 342-9871